¶ How to Pack Road Cases Into Transportation

¶ Preface

In this guide we will first go over the standardized dimensions of trucks in North America & Europe. We will then cover the standard sizes of roadcase used, and finally, we will cover how to correctly pack all of this into a standardized truck.

¶ Standard Truck Sizes

In North America, there are 3 common sizes of truck trailer you will most encounter. While other sizes are possible and do exist, these are the most common sizes transportation companies and truck rental providers have all standardized around, and as such, will be the primary focus of this guide.

¶ 16'

often also referred to as a 3 ton

These trucks commonly do not require specialty/commercial drivers licenses, and as a result, typically have a significantly lower weight limit. They are popular for the smallest of shows, and day to day item transfer, but can be inconvenient to use on site as a result of their small size.

¶ 26'

often also referred to as a 5 ton

While both the same dimension, these trucks are commonly available in two different versions from most major transport rental providers. As licensing of vehicles is most often limited by weight, these trucks are often available at a lower GVWR (gross vehicle weight rating) for non speciality/commercial license holders to be able to drive. It should be noted that trucks in such state are very easy to load overweight, and should be used very catiously. The second and more common option available is this same truck with its full factory certified GVWR. These versions often require specialty/commercial licensing, depending on your region.

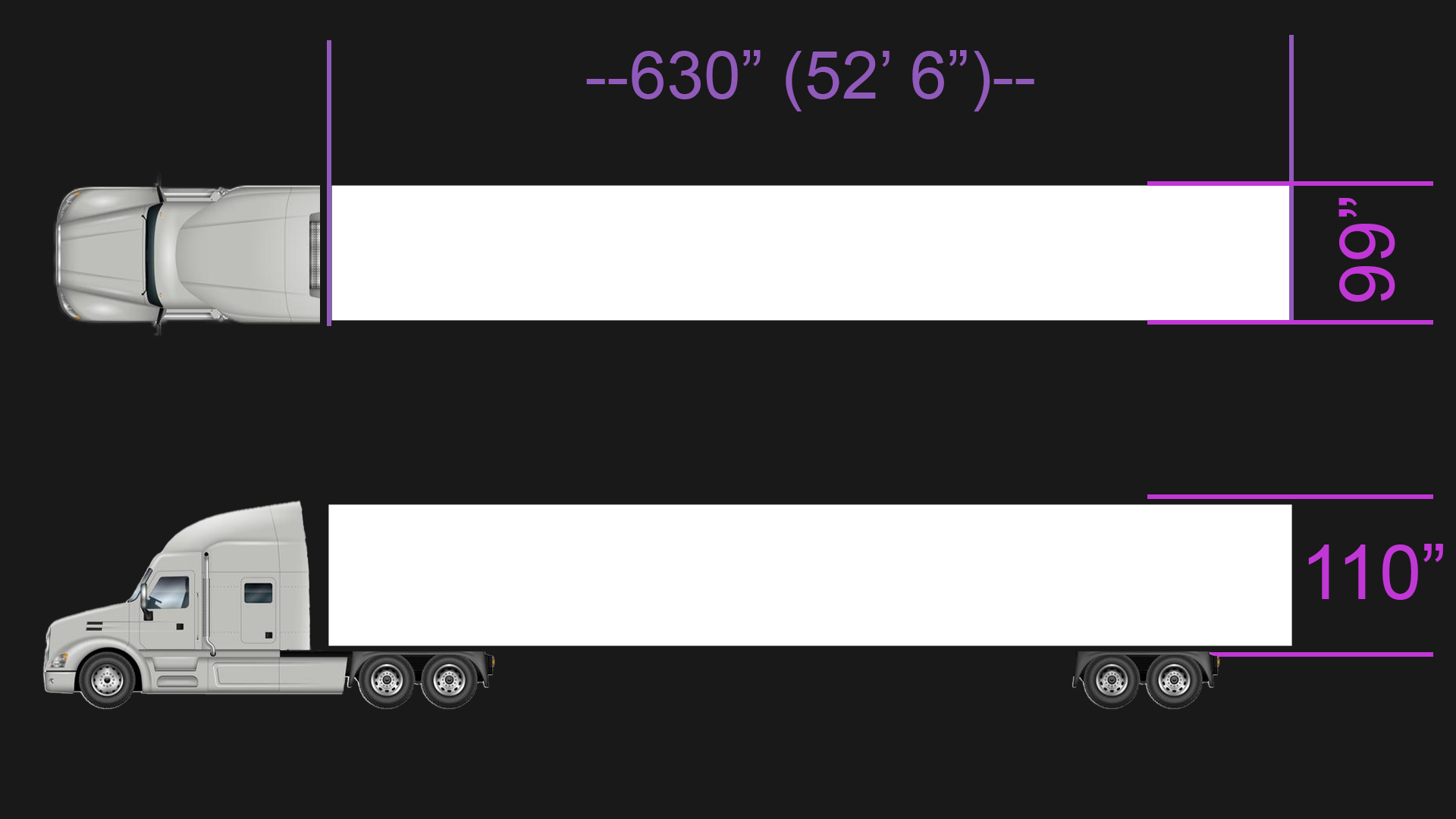

¶ Semi

often also referred to as just a "trailer"

dimensions shown as interior

¶ Standardizing Load Sizes

All road cases should be measured from the absolute edges, including the outside of the balled corners, if present.

¶ Standard Case Heights

In all case dimensions, standard road cases typically run 24" tall, not including the casters. Some companies will also inventory "high top" versions of their 48" x 24" cases, typically 32" tall, which are normally reserved for use on items that are already tall in nature, where needing to reach the bottom of the case is less important.

¶ 48" x 32"

often also referred to as a "cadillac"

¶ 48" x 24"

often also referred to as a "standard", "half pack", or "48"

¶ 32" x 24"

often also referred to as a "third pack", or "32"

¶ 24" x 24"

often also referred to as a "quarter pack", "half-standard", "24", or "MUT" (abbreviated 'multi use trunk')

¶ 24 x 12"

¶ How to Load A Truck

Correctly loading a truck is crucial to the speed at which a show will be able to load in/out, how many trucks will be needed, and the ultimate safety when the truck is in motion. It is important to note that in North America, the driver of a truck typically has a legal responsibility to know what their hauling, and to ensure the load is safely secured. Ultimately, the driver of the truck always has the final say on how the truck will be packed, but this guide outlines some suggestions and best practises that can help educate this process.

¶ Weight Distribution

Crucial to the safety of a truck is how the load is distributed throughout the trailer. Trucks are most stable when the heaviest section is closest to the driver, and handling is most predictable when the weight on either side of the trailer is relatively even. Take time to ensure that when loading a truck the heavier items are not all on the left or right side, a 50/50 mix down each side is best. When stacking items, its important to remember that not all locations may have access to forklifts, and as such, care should be taken to ensure any cases stacked ontop of another should be lighter, the heaviest of cases should be left to the bottom of the stack always to prevent uneccesary human lifting.

¶ Order of Items

One of the biggest markers of a good truck pack is the order in which the truck has been packed. Analyzing the flow of a typical production, the first thing that happens on site is the rigging team begins attaching motors to their designated points in the ceiling. Shortly following this, audio attaches their PA, video attaches LED walls, and LX positions their trussing. An efficient truck pack will keep this in mind, and will pack rigging hardware and motors closest to the door, allowing first access to whats first needed on the show floor. Closer to the back of the truck you'd find specialty scenic, lighting ground packages, staging, cameras, and similar gear that typically wouldn't be installed until after other major processes, such as points taking to trim, have already taken place. This concept should also extend more broadly when planning a multi-trailer pack. While it may be tempting to designate one truck to audio, one to video, one to lighting, one to miscellaneous staging/rigging/scenic, consider that not all venues have the infrastructure to have all trailers docked and open at the same time, a more logical approach to something like this may be the first trailer containing rigging, lighting pre-rig, and line arrays, while the second trailer contains non pre-rig truss, led wall, and flown soft goods. Only on the later trailers would you begin to hold technical racks, consoles, lighting ground packages, cameras, staging, ground scenic, etc. An important addendum to this, is worktrunks, tool chests, and communications tools such as two way radios, these items should always be the absolute first thing off of trucks, and should always be the absolute last thing on trucks, as these will contain items neccesary to safely commence the load-in/out, such as diagrams/plots, tools, PPE, first aid, and communications equipment.

¶ Non Standard Cases

¶ To-Do

- add lots of pictures

- clarify the hecc out of this when its not 5am